The Challenge

Many industrial installations and infrastructure require an increased inspection regime due to end-of-life concerns or life extension. Traditionally, this is done with physical inspectors who inspect these assets via rope techniques, scaffolding, cherry pickers, or on foot. Moreover, humans are “limited” and never have the same coherence. Many items to be inspected are in hard-to-reach places, making thermal-graphic inspection difficult or often impossible. Visual inspections often cannot reveal everything. Additionally, costs with traditional techniques are high.

The Solution

With a thermal-graphic camera, the temperature of an object can be mapped, which is not possible with a visual camera.

The Technology

Thermography is a contactless measurement method that maps temperature. This is done with a thermal-graphic camera equipped with an infrared light sensor capable of analyzing wavelengths. The camera provides a thermogram: a visual representation of the present temperatures.

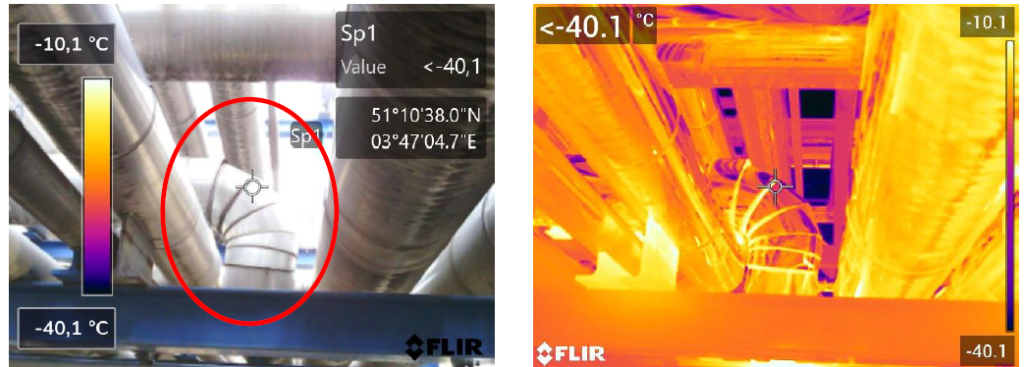

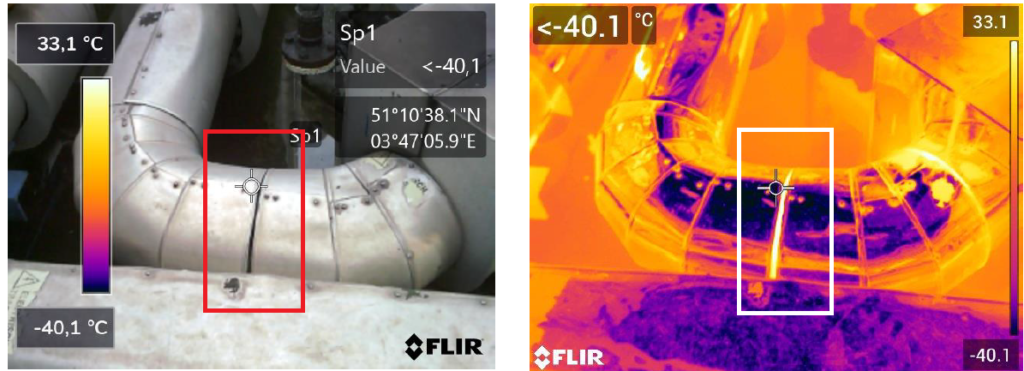

For a thermal inspection, we can use a handheld thermal camera when the asset is easily accessible. For hard-to-reach places, we attach a thermal camera to our drone. From the air, you see different angles, and you have a nice ‘helicopter view.’ These devices always take an accompanying visual photo so that you can clearly see where the damage is found and what might be the cause.

Thermal image of a hotspot in a district heating network. Missing insulation or a leak

is likely the cause.

Furthermore, a thermal inspection depends heavily on various parameters, some of which can strongly influence the result:

- Emissivity: is a property indicating how much radiation comes from an object and is not reflected. A lower value indicates that a larger portion is reflected, while a high value indicates that a lower portion is reflected.

- Reflective Temperature: Each material has a different reflectivity. It is logical that shiny materials such as stainless steel tanks cannot be properly inspected.

A visual and thermal image side by side. Due to the high reflectivity of the stainless steel

panel, you see the complete reflection of the thermographer.

- Weather:

Wind and Rain: In windy or rainy conditions, we cannot fly our drone. When it has recently rained, the asset is also wet, and it dries unevenly. This gives a distorted view of a thermogram.

Humidity: The relative humidity in the measurement environment must be low enough to prevent condensation in the air (mist), on the object being measured, on the protective glass, or on the lens of the thermal camera. A fogged lens (or protective glass) can prevent some of the infrared radiation reaching the thermal camera from being received, as the radiation does not fully penetrate the water on the lens.

Ambient Temperature: Ideally, the temperature contrast should be as high as possible. Therefore, detecting cold leaks is best done on a warm summer day, and heat losses are best detected on a cold winter day.

Sunlight: sunlight provides a lot of warmth on the sunny side and thus distorts the image. A cloudy day is preferable.

- Camera Type: Depending on the situation and expectations, various devices can be used. This can range from measuring range to ‘Field of View’ and resolution. Together we determine which camera best meets your expectations.

The Benefits

- Very accurate visualization of invisible defects

- Combination of visual and thermal images possible

- Very coherent data collection makes comparing defects over time much simpler and more insightful

- Inspection of overall condition, exposed rebar, moisture ingress, crumbling, corrosion

The Use-cases

To capture and interpret these thermal images correctly, it is best to use someone who knows about it. Skyebase has experience with thermal inspections and has trained level 1 thermographers.

A thermal inspection is particularly interesting for:

- Detecting underground water leaks

(project de watergroep – inspection of underground water pipe) - Detecting damaged insulation above ground

(project Total – Visual and thermal inspection of a pipe rack)

(project Total – Inspection of a tank park)

(project Exxon mobil – thermal inspection of a ducting system)

(project Nippon gases – thermal inspection of coldboxes) - Detecting cold bridges or leaks in buildings

(project – inspection of an apartment)

(project – inspection of an industrial building) - Detecting damaged insulation or leaks underground

(project – heat network inspection in the antwerp region)

(project MIROM Roeselare – inspection heat grid) - Detecting pollution

(project Port of antwerp – oil spill detection) - Detecting poorly functioning equipment or components of an asset.

– Solar panels

– Flare pilots (project – flare inspection)

As a result, a report can be provided with thermal and visual images displayed side by side.