UT Measurements

THE CHALLENGE

In the industry, wall thickness measurements need to be conducted regularly for statutory testing or inspections. To perform these thickness measurements (TMLs, Thickness Measurement Locations) or corrosion surveys, these locations must be quickly, yet safely, accessed to avoid jeopardizing the continuity of the (production) process.

Specifically, for TMLs that are difficult to reach or pose a danger to inspectors, the challenge is the biggest. Consider TMLs at height or in (confined) spaces where there might be hazardous vapors/gases present.

Additionally, there is a growing demand to make TMLs insightful for qualitative (inspection) reporting.

TECHNOLOGICAL SOLUTIONS

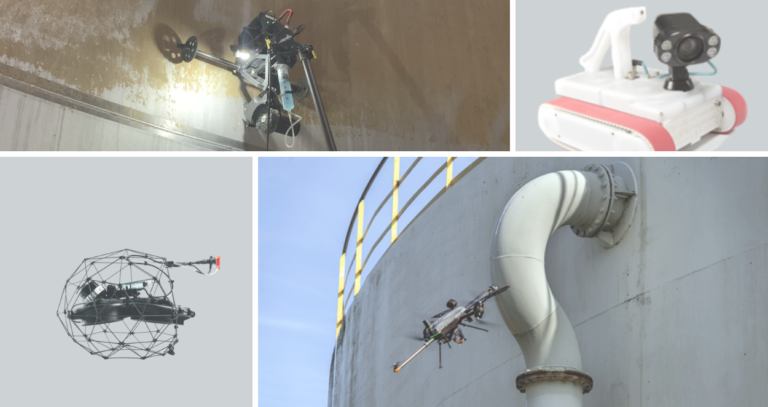

Given the diversity of locations where wall thicknesses need to be measured, there are various solutions. SkyeBase offers the following:

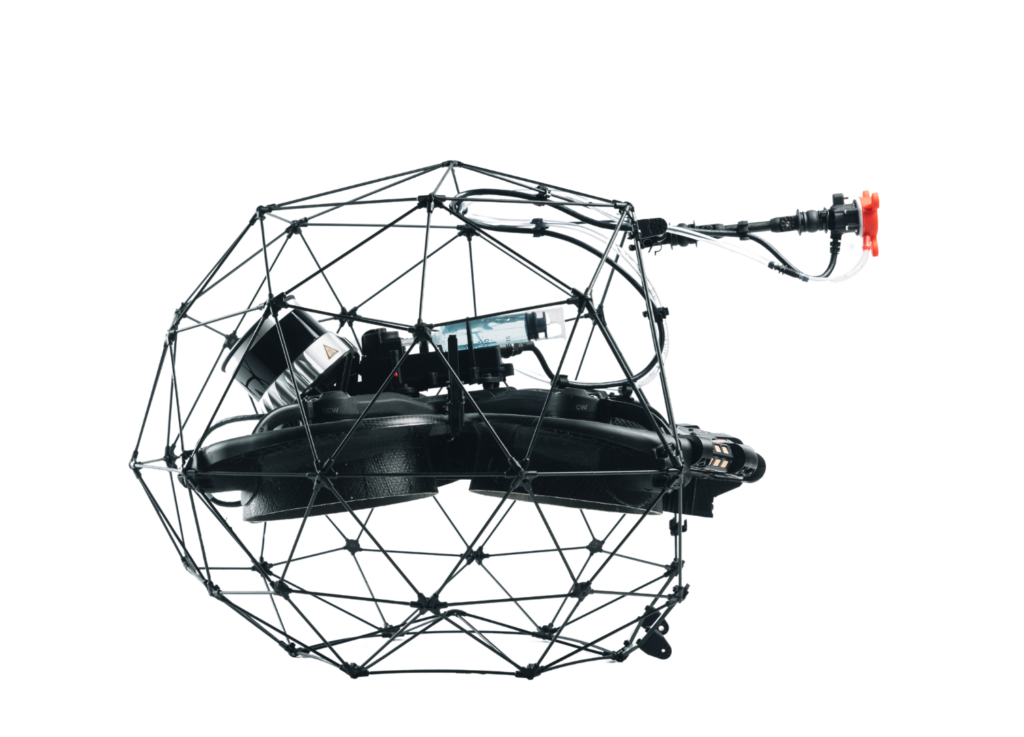

1. Indoor Drone with a UT Payload and grinding Mechanism (Elios 3 UT): Thanks to the UT Payload mounted on our indoor drone (Elios 3), it transforms into a flying UTM (Ultrasonic Thickness Measurement) meter, capable of performing accurate thickness measurements and corrosion surveys, supported by high-resolution images in the most challenging and dark areas. Equipped with the Elios 3 UT-Payload, both wall thickness measurements (A-scan) and cleanings can be carried out, further reducing the chance of downtime. Achieving 350 measurements per day is feasible.

2. Wall Thickness Measurement Stick with a UT Payload and Abrasion Mechanism: To address these challenges, we use a probe with a certified UT (Ultrasonic Testing) device mounted on it. This is an advanced system for Ultra-Precise Tank Monitoring (UTM) thickness measurements. The UT thickness measurement tool is an innovative device that takes the industry to new heights by offering unparalleled speed, efficiency, and precision. With this device, both A-scans and surface cleanings can be performed before measuring, significantly improving the measurement result. Achieving 700 measurements per day is feasible.

3. Outdoor Drone with a UT, EMAT, Eddy Current and DFT Payload: With these payloads, mainly outdoor UT measurements (A-scans) can be performed at great heights and in very difficult-to-reach places. The drone is robust and can perform stable measurements at higher wind speeds. Achieving around 250 measurements per day is feasible.

4. Tank Robot with a UT Probe: This robot can move on steel or stainless steel walls using magnetism or vacuum. It can perform both A-scan B-scan and C-scan and determines the exact position of the measurement.

5. Handheld UT Tool: If a drone is not necessary, a measurement can be performed with a hand-held probe.

EXPERTISE

To perform qualified UT inspections, SkyeBase offers Level 1 and 2 certified inspectors. All equipment is legally calibrated and meets industrial standards and norms. Further information can be provided upon request.

THE BENEFITS

- Faster and safer inspection method for hard-to-reach and/or dangerous inspection locations

- Reduces downtime

- Meets the highest standards of accuracy, quality, and reliability in thickness measurements (compliant with ISO 16809)

- Consistency in data capture

- Cost savings on scaffolding, rope techniques, or aerial work platforms

- No need for manhole guards

- A, B and C-scan at the time of measurement

- Non-destructive measurements

- Real-time measurements

- Data recording and reporting

Share: