In industry, measuring wall thickness is important and in some cases mandatory by law. In many places, however, this is not easy to carry out because of height/safety.

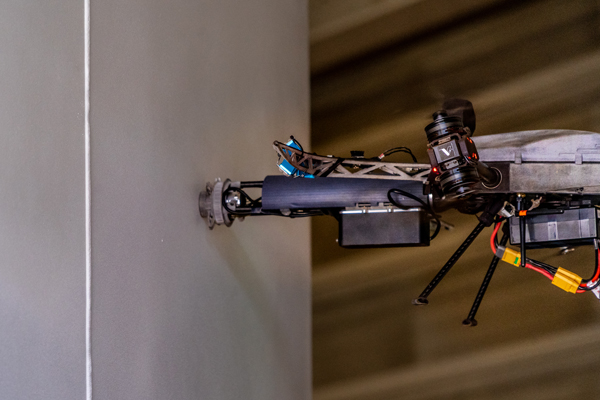

Fortunately, drone technology does not stand still! With our latest drone from Voliro, wall and coating thickness measurements can be carried out at any height.

360° flexibility

The drone is extremely maneuverable and can be positioned at all possible angles. Horizontal, vertical or oblique surfaces, everything is possible! Both inside and outside, this drone can fly stable.

This offers unprecedented possibilities to quickly and easily carry out a wall thickness measurement in hard-to-reach places. e.g. tanks, silos, piping, chimneys, pilons, stacks, etc.

Fly, see & touch

The drone makes contact with the material with the probe, and performs a measurement in a few seconds. 200 measuring points per day are feasible depending on the case. Possible weak points in the tank/chimney can be easily identified.

Measurement methods

The probe can be equipped with a UT, EMAT or a DFT (coating) measuring head.

The probe can be equipped with a UT, EMAT or a DFT (coating) measuring head.

With the UT sensor materials such as metals, plastics and composites can be measured. Measurements methods such as peak, flank, direct and echo-to-echo can be used. With standard sensors wall thickness starting at 2mm can be measured (smaller thickness on request).

The advantage of EMAT is that no cleaning is required and this method measures up to 3mm through corrosion and dirt. Magnetic materials such as mild steel and iron are possible. Measurements methods such as direct, peak and echo-to-echo can be used. With standard sensors wall thickness starting at 2mm can be measured (smaller thickness on request).

Also coating thickness measurements can be performed with a DFT probe.

Reporting

Results will be reported in a PDF document or on our digital platform.

In summary, these are the 3 biggest advantages:

- Safer: no measurements at height by people, but by using a drone.

- Costs efficiency: no rope techniques, installation of scaffolding or aerial platforms needed.

- Reduction of downtime: a drone performs inspections 5 to 10 times faster.

- Total solution: inside and outside measurement are possible.

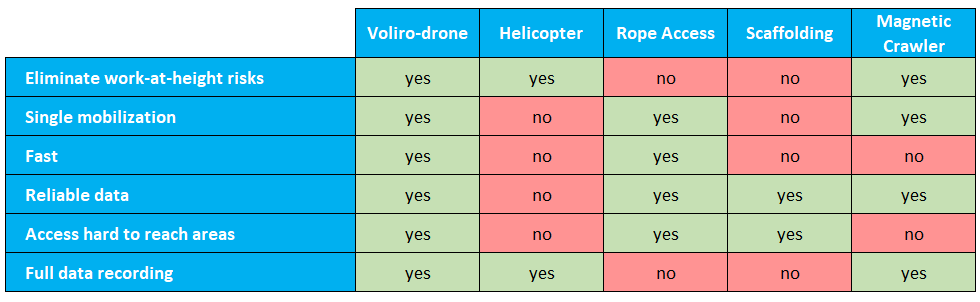

There are 5 ways to perform NDT inspections at height.

The application has the following proven use-cases:

The application has the following proven use-cases:

- Storage tanks and silos: these surfaces are large, relatively smooth and have few obstructions for carrying out measurements.

- Steel chimneys: this application is difficult to achieve with rope techniques and scaffolding and has many large surfaces.

- Pressure vessels: specific places of non-insulated pressure vessels can be reached if there is sufficient space around the tanks.

- Flare stacks: can be inspected in operation leading to major savings in operational downtime. The temperature of the chimney is a factor that can influence the inspection coverage of the structure.

For more information, please contact :

Jean-Louis Weemaes, +32 (0)478-930.994, jean-louis.weemaes@skyebase.be