3D Visualization and Annotation of Defects

Challenges

Identifying damages on large industrial and public assets such as piperacks, flare installations, silos, tanks, buildings, and bridges is a complex task. Traditional inspection methods, where reports are based on individual defect images, are time-consuming and not always effective for drawing easy conclusions for maintenance and repairs.

The Solution

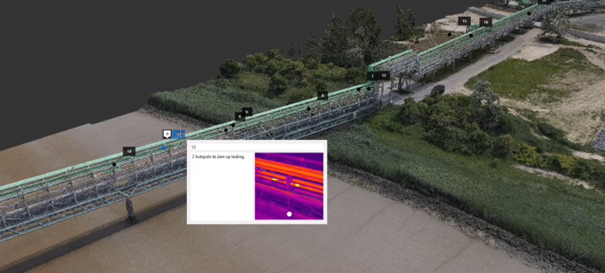

As a leading drone and robot inspection company, SkyeBase has the solution to this challenge. Through photogrammetry and lidar, assets can be captured in 3D. This information can then be processed into point clouds, 3D mesh objects, or ortho photos. This provides inspectors and maintenance personnel with a detailed and structured inspection overview of identified defects in a 3D environment, significantly reducing the chance of missing damages. Inspectors can easily communicate online through this 3D representation and do not need to be physically present on-site. Investments in these innovative technologies are a strategic move for companies to reduce costs and optimize the reliability and predictability of their assets.

Technology

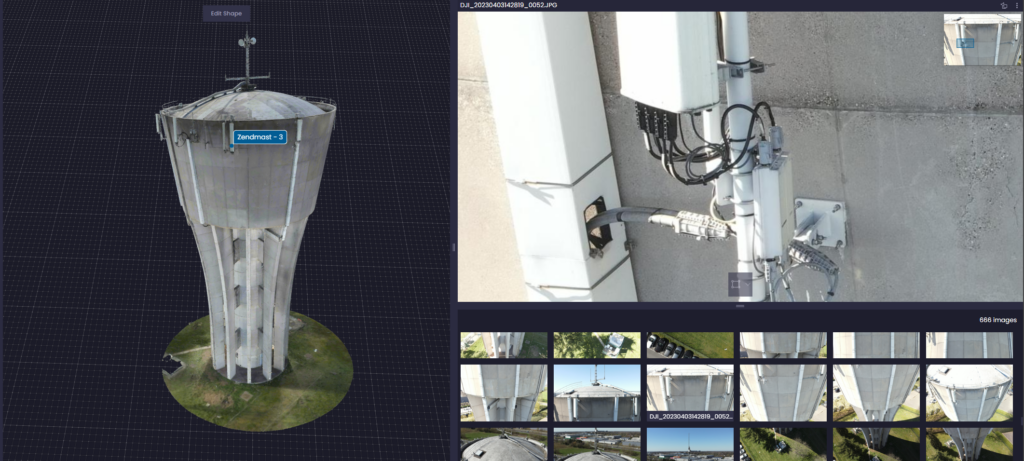

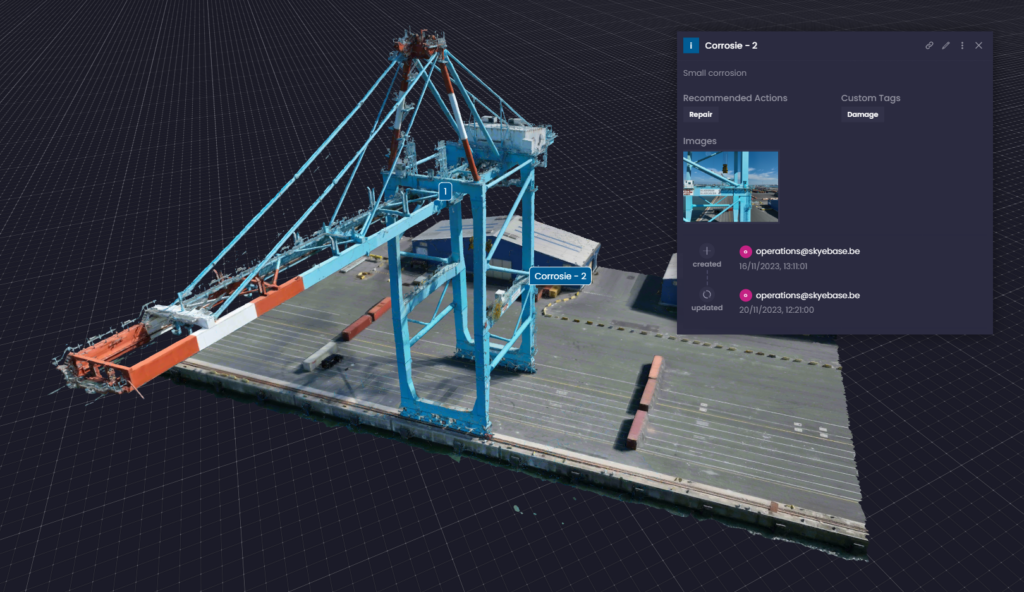

We use realistic 3D models to provide asset managers with a clear overview of the integrity of their assets. Damages and issues can be easily annotated in these models, simplifying the reporting process and minimizing human errors. The 3D model is offered on an online platform, making it easy to work with.

Reporting

Defects from an inspection are annotated on a 3D model and delivered on a platform. The client receives login credentials for this platform, gaining access to the 3D models. Annotations can be made on both the 3D and 2D images. Additionally, actions can be linked to these annotations. Visual damages can be indicated on these models, and measurements can also be taken.

Benefits

Detailed 3D Models:

SkyeBase’s 3D model provides a lifelike and comprehensive representation of the asset. This not only offers insight into the physical structure but also identifies potential issues and allows for thoughtful planning of maintenance actions. The level of detail in the 3D model can be tailored to project expectations.

Optimized Visual Inspection:

The 3D model simplifies and enhances visual inspections. Users can view assets from various perspectives and zoom in on specific details to better understand any defects.

Precise Reporting:

Annotating defects in the 3D model results in highly precise reporting, minimizing errors and accelerating the communication of issue information to stakeholders.

Enhanced Collaboration:

Sharing 3D models with annotations significantly improves collaboration among different team members, including asset managers, technicians, and managers. Everyone has access to identical detailed information. Additionally, measurements can be taken via this 3D model.

Reduced Downtime:

A significant amount of data can be captured in a short time. This data is then processed and analyzed in the office. By minimizing on-site time, the asset can be returned to service much faster than usual.

Cost Optimization:

The ability to quickly and accurately identify and address defects results in cost optimization by limiting unplanned downtime and optimizing maintenance activities.

Cloud-Based Work:

Working in the cloud eliminates the need for a powerful PC to open point clouds. This also makes it possible to easily share point clouds with all relevant stakeholders.

Examples of 3D Models:

If you are interested in testing our 3D Cloud solution or discussing your needs, please feel free to contact us.