THE CHALLENGE

Inspecting storage tanks, whether based on regulations or risk assessment, is a complex process that requires various types of inspections. These include internal and external visual inspections, geometric surveys, and calibration according to applicable standards and legal certifications (EEMUA-159, API-653, Vlarem, PGS 29/31). The variety of inspections needs to seamlessly integrate with each other. However, there is a challenge: coordination and alignment between these inspections are crucial to minimize time loss and operational inefficiency.

THE SOLUTION

In the heart of this challenge, SkyeBase and SGS have joined forces to provide a comprehensive tank inspection solution. This collaboration combines SGS’s technical expertise in conducting regulatory and risk-based inspections with SkyeBase’s expertise in drone robotics, data, and digitalization. This approach aims to ease the burden on the customer and provide a single central point of contact. With abundant expertise and a deep understanding of standards, they deliver results that exceed expectations.

TECHNOLOGY

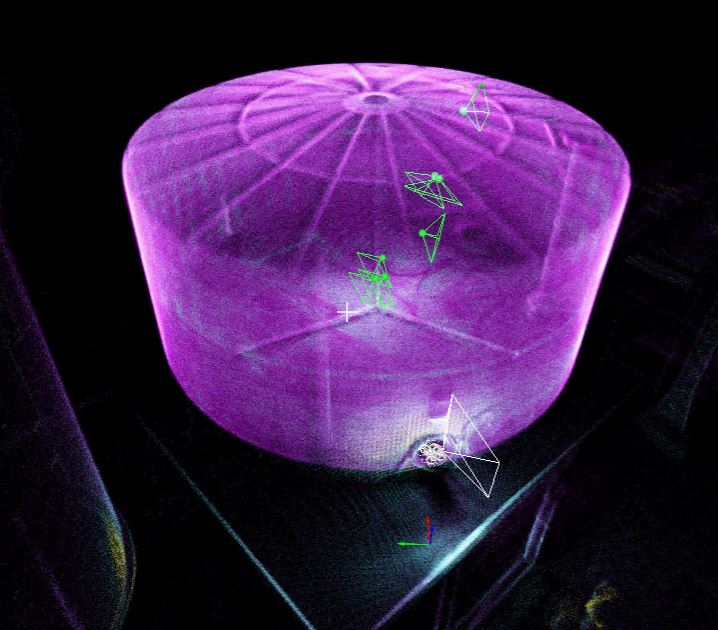

We expand traditional visual inspections with innovative inspection processes using drones and robotics. In addition to more efficient inspections, these new methods will primarily reduce or even eliminate human risks during inspection. We use various types of drones and devices, including indoor and outdoor drones (emission, UT), crawlers, floorscans, and total stations.

REPORTING

SGS, as an ISO/IEC 17020 accredited inspection body, prepares the legal report. In addition to the report, we can create a digital 3D model (digital twin) of the storage tank, visually representing all inspection data and potential defects. This information can later be used for maintenance recommendations.

ADDITIONAL BENEFITS

- Improved Safety: Traditional inspection methods such as working at heights and entering confined spaces are minimized or even eliminated thanks to the use of advanced technologies like drones and crawlers. This significantly reduces the risk to employees.

- Optimal Cost Control: Reducing the need for scaffolding and manning leads to cost efficiency in the inspection process, allowing financial resources to be used more effectively.

- Data Accuracy: Inspection results reporting not only meets legal requirements but also provides 3D visualizations that offer in-depth insights into defects and maintenance needs. This helps in making informed decisions.

- Centralized Data: Centralizing inspection data makes it easier to stay updated on inspection results and facilitates reporting and compliance.

- Atex Zone Risk Assessment: Assessing Atex zones based on risk analysis (TRA) enhances safety and ensures better alignment with standards.