Tank inspections are a crucial component of the maintenance process in various sectors, such as the oil and gas industry, chemical industry, and shipping. Traditionally, these inspections often required costly and time-consuming processes, but thanks to the emergence of drone technologies, this landscape is being transformed. In this blog, we delve deeper into how drones are being utilized for various types of tank inspections, ranging from visual inspections to wall thickness measurements, thermal inspections, and even underwater inspections.

Visual inspections:

One of the most obvious applications of drones in tank inspections is conducting visual inspections. Drones are equipped with high-resolution cameras that capture detailed images of tanks. This enables inspectors to quickly identify issues such as corrosion, cracks, or other defects without the need for human climbers or scaffolding, thereby increasing the safety and speed of the inspection process.

Wall thickness measurements:

Monitoring the wall thickness of tanks is essential to ensure their structural integrity. Drones and robots are equipped with ultrasonic sensors that perform accurate measurements of wall thickness. By collecting this data, inspectors can evaluate the current status of the tanks and identify potential weak points that require attention.

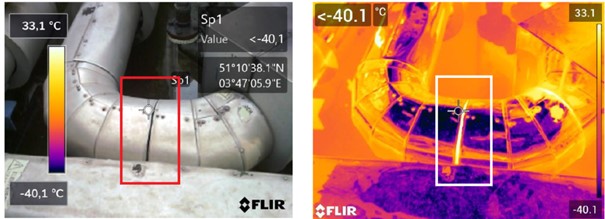

Thermographic inspections:

Thermographic inspections utilize thermal imaging technology to detect hidden problems in tanks, such as leaks or insulation issues. Drones with thermal imaging cameras can quickly scan large surfaces and identify abnormal heat patterns indicating possible issues. This enables inspectors to proactively take action to prevent future failures.

Underwater inspections:

In cases where firewater tanks are filled with water, drones can also be deployed for underwater inspections. Known as ROVs (Remote Operated Vehicles), these underwater drones are equipped with cameras, sonars, and other sensors to evaluate the condition of tanks underwater. This allows inspections to be conducted without the need for divers, improving safety and reducing costs.

Reporting and analysis:

After conducting inspections, it is essential to accurately analyze and report the collected data. Thanks to I-Spect, SkyeBase’s AI-supported asset inspection platform, inspectors can visualize collected data, identify defects, and generate detailed reports for further evaluation.

Through these reports, engineers and operators can gain a thorough understanding of the overall condition of the tanks and identify any potential issues that require attention. These analysis and reporting capabilities play a crucial role in developing maintenance plans and making decisions regarding repairs or preventive measures.

By using advanced reporting and analysis tools, companies can improve operational efficiency, extend the lifespan of their tanks, and minimize unplanned downtime, allowing them to manage their operations more effectively and ensure the safety of their facilities.