Quickscan

In the rapidly changing world of asset management, companies face a continuous challenge: how can they inspect their assets in a cost-effective, qualitative, and efficient manner? Whether it’s inspecting industrial installations or infrastructure, one innovative solution stands out: semi-automatic drone flights.

THE CHALLENGE

Traditional inspection methods for asset management often require significant human involvement and can be costly and time-consuming. The duration of an inspection can be long when flown manually, and reproducibility, crucial for trend analysis, may not be perfect in subsequent inspections. Moreover, human inspection is susceptible to errors, leading to missed issues and higher long-term costs.

THE SOLUTION

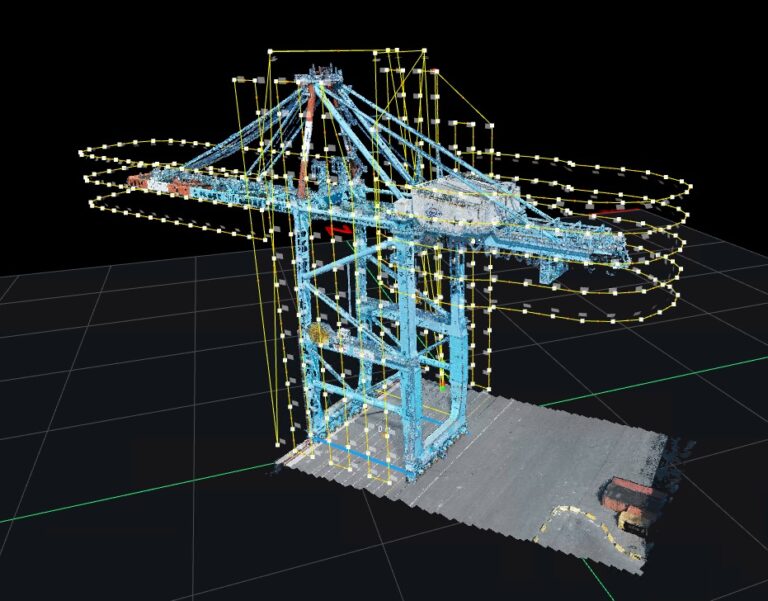

SkyeBase offers an innovative solution to these challenges. Using advanced software and drone technologies, SkyeBase enables semi-automatic drone flights for asset inspections. This software allows users to create detailed flight plans, defining specific locations, altitudes, and flight paths. This means that drones can operate autonomously with minimal human intervention. (Static) assets can be consistently flown in the same manner.

THE TECHNOLOGY

SkyeBase employs advanced technologies, including GPS and advanced sensors, to ensure precise and reliable flight results. Thanks to this technology, drones can autonomously avoid obstacles and operate precisely according to the defined flight plan. This semi-automatic approach not only saves time and optimizes data capture for trend analysis but also minimizes risks of accidents.

THE BENEFITS

The benefits of semi-automatic drone flights are impressive. Firstly, this leads to significant cost savings. Reduced human involvement and more efficient, faster inspections mean lower operational costs. Moreover, inspections can be conducted more frequently, increasing the chances of detecting issues at an early stage, ultimately leading to cost savings. Faster on-site data capture reduces asset downtime, and image analysis can be performed in the office. Consistent inspection methods make it easier to track defect evolutions.

EXEPERTISE

During a project at Cargill, the following steps were taken for a visual inspection of a concrete silo to assess the integrity of the concrete:

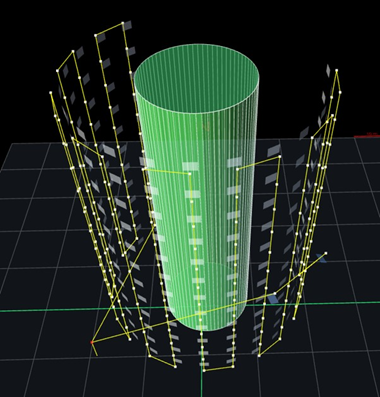

1. Automatic data collection via a drone with a visual camera.

2. Creating a 3D model.

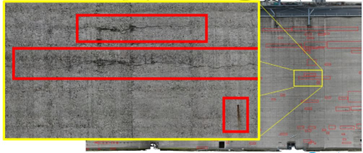

3. Generating an orthophoto from the 3D model, followed by annotating defects on the orthophoto.

Share: