Situation:

Storage tank terminals and refineries are expecting a strong increase of inspection and maintenance efforts for the coming decades. Many asset integrity assessors and operators are going to retire.

Solution:

The Falcker asset care platform helps to monitor tank deficiencies and degradation and optimize maintenance planning

Why: the platform provides quantitative insight to:

- Increase asset availability

- Improve people and environment safety

- Improve inspection and maintenance processes

- Reduce inspection costs and increase the efficiency of inspectors

- Enable compliant asset management

How: the way we work:

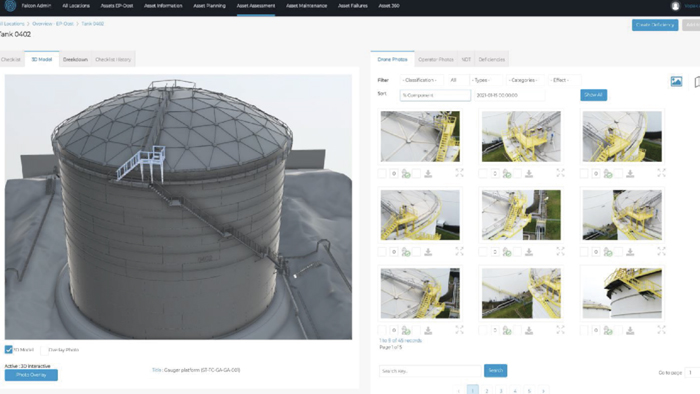

- We digitize the assets and create the so-called “digital twins” in the Falcker Digital Asset Care Platform.

- We use sensors and robotics to obtain inspection data. This ensures more frequent and consistent inspections to facilitate optimal planning.

- The generated data is “mapped” with the digitized asset components, which makes it possible to predict maintenance needs.

What: products & services

- Falcker Digital Asset Care Platform software subscriptions (assets, users, data usage)

- Software and hardware implementation for automated data collection

- Asset integrity monitoring:

- Visual inspections

- Second containment volume

- Degradation measurements

- (Gas)emission measurements

- Geometrical analysis

Benefits for our customers:

- More efficient and predictable inspection (management) and maintenance processes

- Safer asset inspection (less Atex zone 1 hour – working at height)

- Improved data quality, integrity and compliance

- Increased asset availability: better scoping, reduce downtime, less unexpected

- Potential overall cost reduction of 30%