What is 3D mapping with drone used for?

3D mapping with drones has transformed the way it maps bulk volumes and infrastructure. Thanks to advanced drones with specialized sensors, such as LiDAR and photogrammetry cameras, it is now possible to visualize bulk volumes and industrial installations with unparalleled accuracy. In this blog, we delve deeper into how 3D drone mapping is applied in the industry, with a focus on bulk volumes and infrastructure.

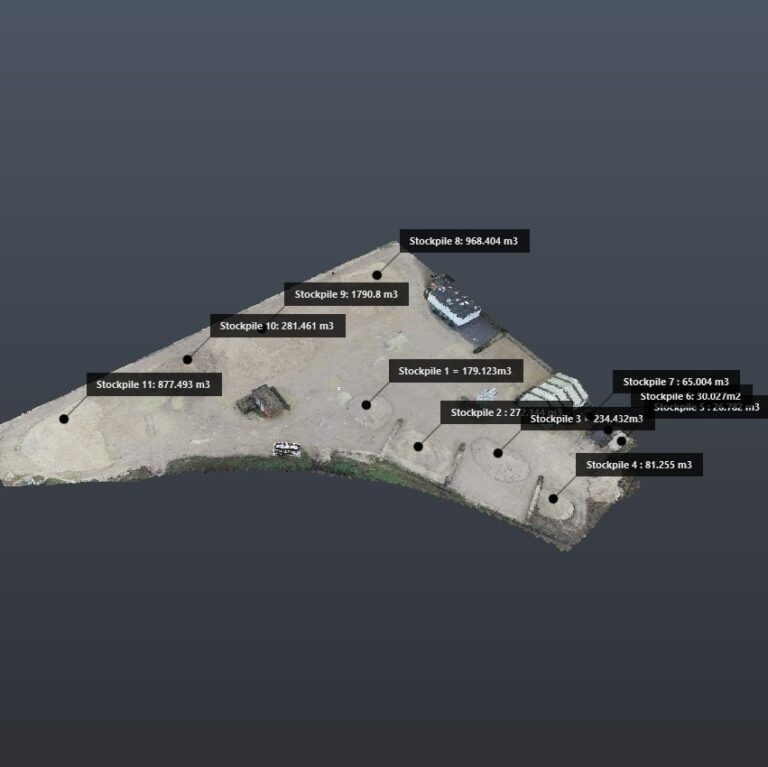

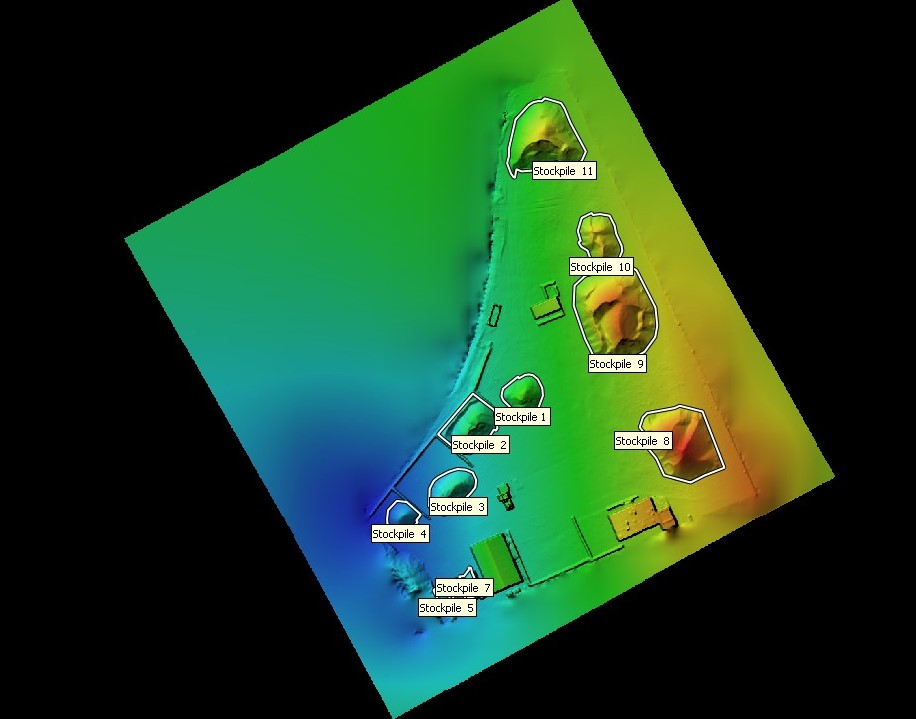

The integration of drone technology has significantly improved efficiency and accuracy in various industries. For bulk volumes, drones equipped with LiDAR and photogrammetry cameras can quickly and precisely measure and visualize stockpiles of materials like ore, coal, gravel, and sand. This allows for better inventory management and real-time monitoring, enhancing productivity and reducing waste.

In infrastructure, drones have revolutionized inspections and maintenance. They can swiftly survey factories, power plants, and refineries, creating detailed 3D models that highlight issues such as structural damage or wear and tear. This reduces the need for manual inspections, improves safety by keeping workers out of hazardous areas, and helps in planning maintenance more effectively.

3D Drone Mapping in the Industry

Mapping of Bulk Volumes:

In mining, industry, construction, and the energy sector, 3D drone mapping plays a crucial role in mapping bulk volumes, such as ore, coal, gravel, sand, and more. Drones can quickly and accurately collect data about the size and location of these valuable resources. This data is essential for optimizing operations, leading to more efficient extraction and reduced waste. By providing precise volumetric measurements, drones enable better inventory management and allow for real-time monitoring of stockpiles. This helps in making informed decisions regarding resource allocation and logistics, ultimately enhancing productivity and cost-efficiency. Moreover, the use of drones in these sectors reduces the need for manual surveys, which can be time-consuming, expensive, and potentially hazardous.

Mapping of Infrastructure:

3D drone mapping is also used for surveying, inspecting, and documenting (industrial) infrastructure, such as factories, refineries, power plants, industrial and civil buildings. By creating detailed 3D models, companies can effectively manage their facilities, plan maintenance, and improve safety. It allows them to detect and address issues such as wear and tear, corrosion, and structural damage early on. This proactive approach to maintenance helps prevent costly repairs and downtime. By providing a bird’s-eye view and hard-to-reach perspectives, drones enhance the thoroughness and accuracy of inspections, contributing to better asset management and operational efficiency.

Benefits of 3D Drone Mapping in the Industry

- Accuracy: 3D drone mapping provides highly accurate data, enabling companies to obtain precise measurements for inventory and analysis of raw materials and industrial installations.

- Efficiency: Thanks to drones, companies can quickly map and inspect large areas, saving valuable time and resources.

- Safety: Using drones reduces workers’ exposure to potentially hazardous environments, improving workplace safety.

- Cost Savings: By minimizing human labor and reducing waste, companies can save costs.

- Real-Time Monitoring Capability: 3D drone mapping allows companies to monitor changes in bulk volumes and infrastructure in real time, enabling them to proactively respond to potential issues and changes.

Conclusion: 3D Drone Mapping

In summary, 3D drone mapping has transformed the industrial sector. With unparalleled accuracy, efficiency, and safety, this technology has become an essential tool for companies striving for improved operational processes and cost savings. It has become an indispensable tool for those looking to tackle the challenges of modern industry and facility management.